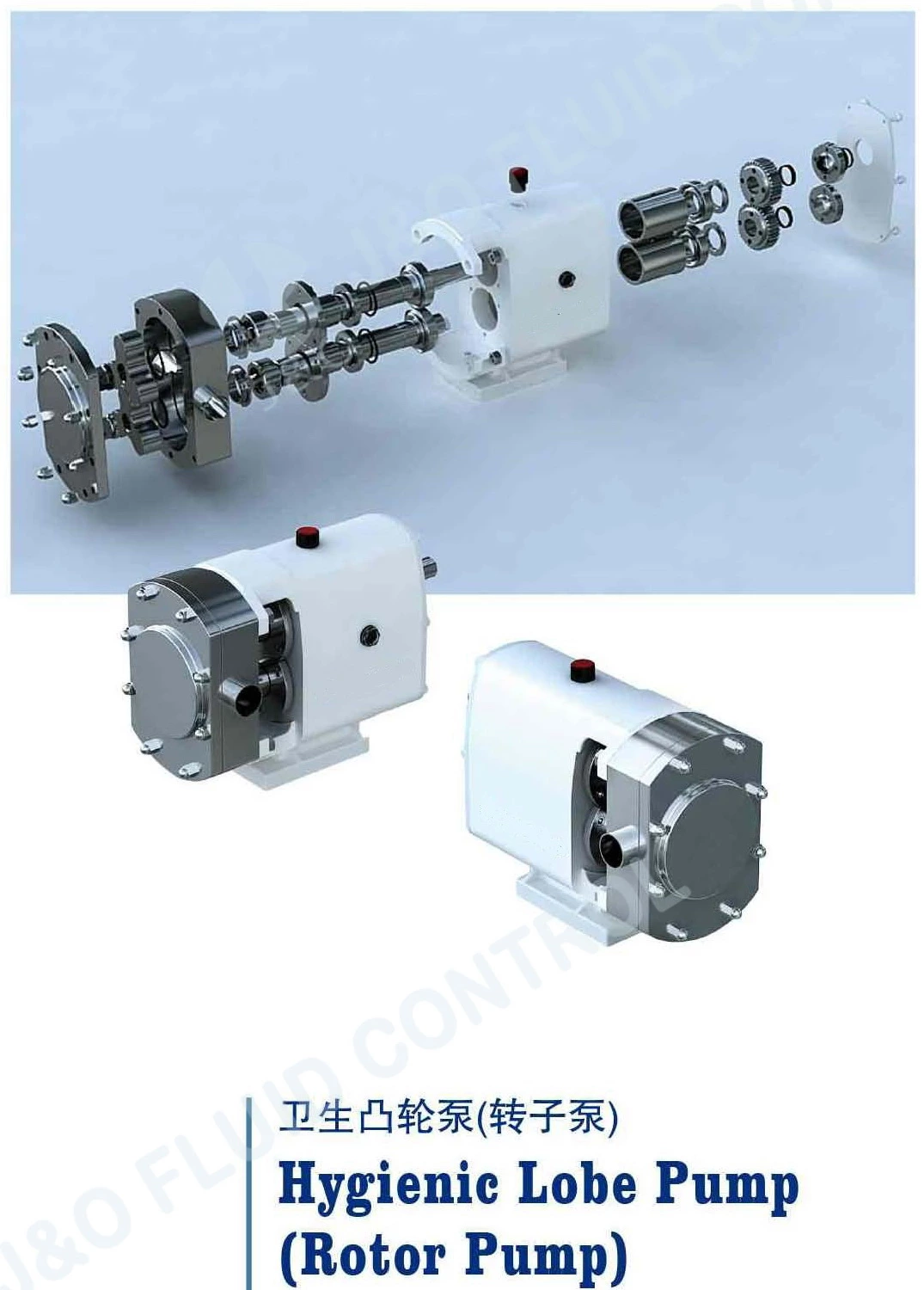

Stainless steel rotor pump, rotor pump, Cam rotor pump

Operation Principle

Rotor pump is also named colloid pump, three-lobe pump, sole pump, etc. When the 2 simultaneous reverse rotating rotors (with 2-4 gears) revolve, it produces suction force at the inlet (vacuum), which intakes the material delivered. The 2 rotors divide the rotor housing into many smaller parts and revolve in the sequence of a-b-c-d. When it revolves to position a, only housing | is filled with medium, when it revolves to position b, housing B encloses medium, and finally it goes to position d, then housing A, B and || are interlinked and the medium is transported to the outlet. As this process is repeated, medium (material) is transported continuously.

PUMP SPECIFICATION:

Pump type: Rotary

Capacity: 5, 000 liters per hour maximum

Rotor case material: Stainless steel 316

Port size: 50 mm SMS

Port orientation: Vertical

Seal Type: Carbon Vs. Stainless Steel

Rotor form / material: Trilobe / 130 C / Stainless steel 316

Rated Pressure: 10 Bars

Elastomer Materials: EPDM

Shaft orientation: Left

Internal finish: Standard

Drive Motor Specification:

Driver Type: Variable speed Geared Electric Motor

Driver Power: 2.2 Kw.

Driver Speed: 300 Rpm at 50 Hz

Electrical Supply: 380 V / 3 pH / 50 Hz

Mounting: Inline stainless steel Baseplate

Transmission: Flexible coupling in stainless steel Coupling guard