Proportional Control Pneumatic Female Angle Seat Valve With Positioner

- Brand:

- J&O

- Material:

- SS304 / SS316L

- Connection:

- Female

- Gasket:

- PTFE

- Working Temperature:

- -10 degree C ~ +180 degree C

- Working Pressure:

- 0-16bar

- Operation:

- Pneumatic

- Payment:

- T/T, L/C, Western Union

Proportional Control Pneumatic Female Angle Seat Valve

- Stainless steel angle seat valves can be used to deliver millions of cycles of operation in demanding applications such as steam, water and aggressive media. They are ideally suited for vacuum applications and can be used in fast acting applications up to 1000 cycles per hour with expected life of over 10 million cycles. They are used in many industries, including food & beverage, chemical, oil & gas, water & sewage etc.

- Angle seat valves are operated pneumatically such that air pressure is used to control the piston actuator, which lifts the valve plug off its seat. Normally Closed (NC) valves usually have the valve closed in unpressurized conditions and use a spring to return the valve to the rest state. Normally Open (NO) valves have the valve opening always open unless air pressure acts to close it. A NO valve can be obtained if the spring is placed on the opposite side of the piston actuator. Double Acting valves can be used to handle flow in both directions. These valves have no spring and depend on the supply air to determine the valve position. These configurations influence the pressure rating of the valve. Flow up and under the valve (causing valve to open) will reduce water hammer effect but reduces the maximum working pressure of the valve by typically 50%. However, fitting a strong return spring will help increase the working pressure but a larger actuator will be required to overcome this increased spring strength. With flow over seat (causing valve to close), a full working pressure is achieved and water hammer can be reduced by restricting the compressed air supply flow.

- Positioner receives 4-20mA electrical signal from controls system and coverts them into air signals to control the valve and make precise flow adjustment using the adjustable seat.

- Convenient to adjust and easy to operate. Stable operation with vibration resistance. The unique design of adjustable seat establishes a proportional linear relationship between open/close state of the valve with the flow rate, achieving precise flow adjustment.

- If the valve body needs to be taken off during installation, please recalibrate the zero-point. Keep the positioner upright at all time. To ensure accurate adjustment, please install the valve in below seat direction. please ensure water proof of the positioner.

Technical Data

| Valve Body Material: | 1.4404/1.4301, SS304/SS316L |

| Seal Material: | PTFE |

| Max working pressure: | 0-16bar |

| Medium Temperature: | -10 degree C ~ +180 degree C |

| Availably connection: | weld, thread, clamp, flange |

| Operated: | Pneumatic |

| Medium: | Neutral gas, air, water |

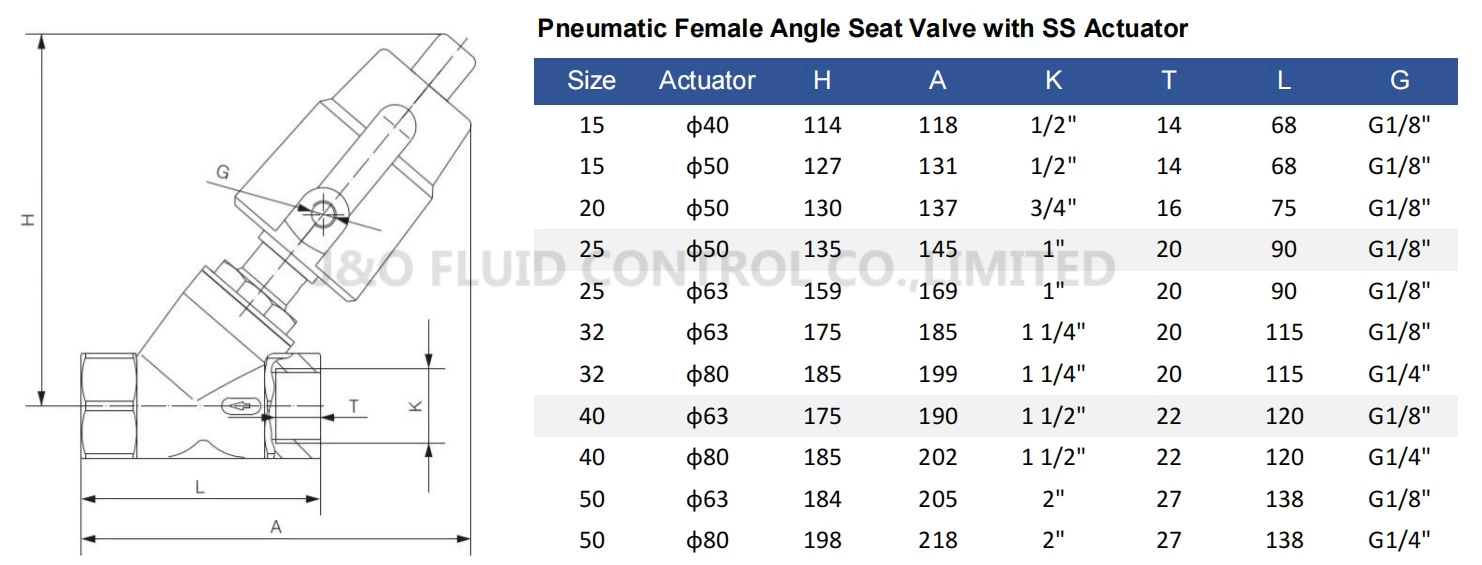

Product Parameter